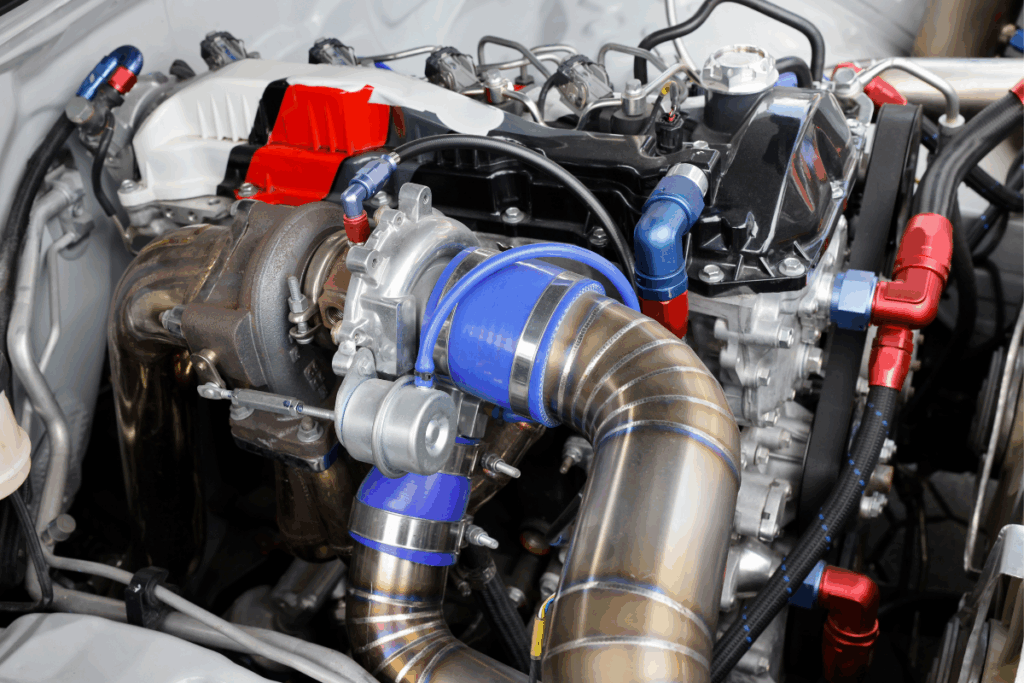

Turbocharged engines have become a staple in modern Mercedes-Benz vehicles, offering a balance of power, fuel efficiency, and smooth performance. However, Mercedes-Benz turbo failure is an issue that can lead to reduced power, excessive smoke, and costly repairs.

If you own a Mercedes-Benz and suspect turbo issues, understanding the causes, warning signs, and potential fixes can save you from a major breakdown.

Quick Symptoms You Shouldn’t Ignore

- Sluggish acceleration and weak passing power that hurts performance

- Excessive exhaust smoke (blue, white, or black)

- High-pitched whistle, siren, or grinding unusual noises

- Check engine light or engine light with boost pressure or airflow codes on the dashboard

- Surging, limp mode, or erratic boost delivery that forces the engine to work harder and burn more fuel

- Oil residue/oil leaks around the turbocharger or in charge pipes/intercooler

Core Causes and Warning Signs

Most turbo problems don’t start with a bang—they creep in. Dirty or low oil, debris in the intake, and uncontrolled boost quietly wear the turbo down until power drops, excessive exhaust smoke appears, and the check engine light flickers on.

Oil Problems & Debris

One of the primary reasons turbos fail in Mercedes-Benz models is oil-related issues. Turbos rely heavily on a steady supply of clean, high-quality oil for lubrication and cooling.

If the engine oil is dirty or degraded, or the level is too low, it can lead to premature wear of the turbo bearings, resulting in failure. Regular oil changes using the manufacturer-recommended oil type can significantly extend the life of your turbo.

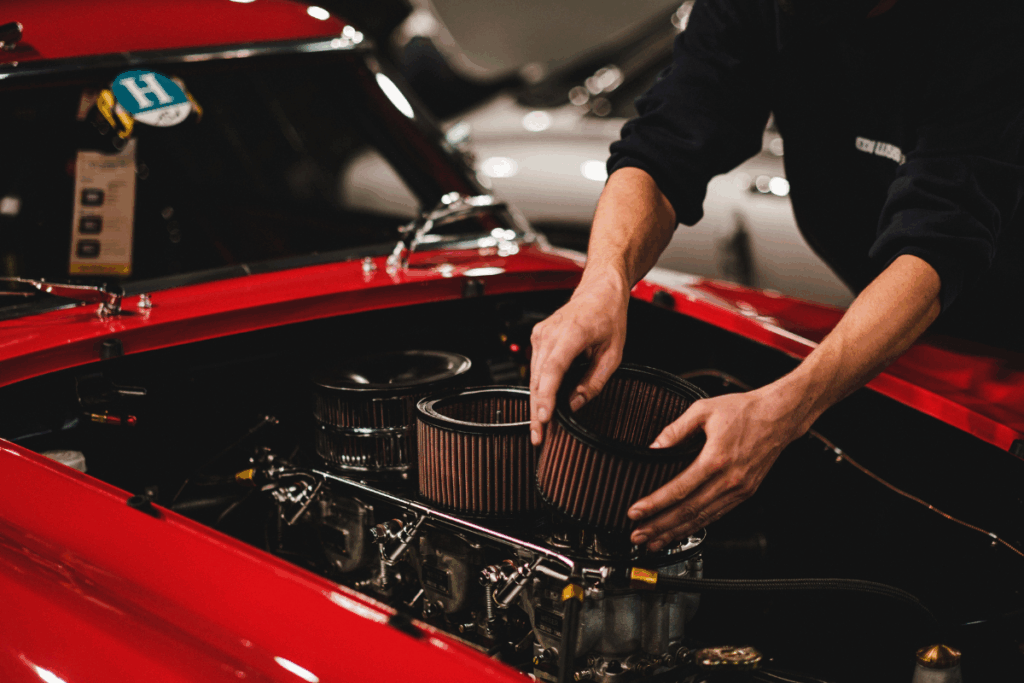

Another major cause of turbocharger failure is foreign object damage. Dust, debris, or even small metal particles can enter the turbocharger through a damaged air intake system or a faulty air filter, leading to serious damage to the turbine blades. Ensuring that your air filter is clean and intact keeps abrasive air out of the engine, the turbo, and the combustion chamber.

Boost Pressure or Overboosting

Excessive boost pressure, or overboosting, is another factor that can destroy a turbo unit. If a turbocharger is working harder than it was designed to, it puts extra stress on the turbine and compressor wheels, leading to cracks, warping, or total failure. That loss of control can hurt fuel efficiency, force the engine to use more fuel, and spiral into further damage.

Overboosting can occur due to a malfunctioning wastegate, faulty sensors, or aftermarket modifications that push the turbocharger beyond its limits. That’s why it’s crucial to have your vehicle checked if you notice unusual acceleration surges or higher-than-normal boost pressure levels.

When a failing turbo starts to go, it gives off several warning signs. One of the most common symptoms is a loss of power. A turbocharged engine relies on the turbocharger to compress air and add performance, so when it fails, your vehicle may feel sluggish, especially during acceleration.

Color of Smoke = Fast Clues

Another clear indicator is excessive exhaust smoke. Depending on the issue, a failing turbo can produce blue, white, or black smoke.

- Blue smoke usually means oil is leaking into the turbo and burning in the exhaust.

- White smoke can indicate coolant leaks or internal engine damage.

- Black smoke is typically a sign of unburned fuel caused by a failing turbo.

Leak In the Boost System

A high-pitched whining or whistling noise is another telltale sign. If your car sounds like it has a siren under the hood, it could mean turbo bearing wear or a leak in the boost pressure system. Similarly, check engine light/engine light warnings and fault codes related to pressure and airflow often point to turbocharger issues. Ignoring these early symptoms can lead to catastrophic engine damage and costly repairs.

If you suspect turbo failure, the first step is to inspect the turbo and surrounding components. Mechanics will usually check for oil leaks, loose connections, or excessive shaft play in the turbocharger.

If the turbo has seized or suffered extensive damage, a rebuild or complete replacement is necessary. In some cases, replacing supporting components such as the intercooler, hoses, and sensors may also be required to ensure everything functions properly and to prevent further damage.

What Else Commonly Causes Mercedes-Benz Turbo Failure?

Not every failed turbo comes down to oil or overboost. Hidden culprits—wrong oil specs, coked feed lines, rising backpressure, and misreporting sensors—quietly push the turbocharger past its limits. Spot these early and you protect the engine, restore clean boost, and avoid expensive repairs.

Incorrect Oil Spec or Extended Intervals

These engines depend on the correct Mercedes-approved oil (MB 229.xx). Wrong spec or long intervals create sludge, starve the bearings, and accelerate seal wear—problems that quickly harm your vehicle’s performance and efficiency.

Coked Oil Feed/Return Lines

Hard driving and hot shutdowns bake oil in the lines. Flow drops. Bearings suffer. Replace suspect lines with the turbocharger or during a rebuild.

Excessive Backpressure (Cat/DPF Issues)

A clogged catalytic converter or DPF raises backpressure and heat. The turbocharger works harder and fails sooner. If the DPF is blocked, address it promptly.

Sensor and Actuator Faults

Failing MAP/MAF sensors, vacuum leaks, or a bad electronic actuator upset control, triggering surging, limp mode, and overboost. Modern Mercedes are equipped with monitoring that will possibly flag related faults early—use that to catch the issue early and save on cost.

Proper Maintenance

Keep your turbo healthy with simple habits and routine diesel engine maintenance. Short bursts of care go a long way, help the engine deliver the performance you expect and prevent expensive repairs.

- Oil on schedule: Follow Mercedes service intervals and use the correct, high-quality diesel engine oil and filter. Clean oil protects bearings and seals.

- Warm-up first: Drive gently for the first few minutes. Let oil reach temperature before heavy throttle.

- Cool-down after hard runs: After highway speeds or towing, idle about 60 seconds before shutoff. This prevents oil coking and heat soak.

- Clean air in: Replace air filters on time. Inspect intake boots and clamps so debris can’t reach the compressor wheel.

- Fix leaks fast: Split charge pipes or loose clamps make the turbo work harder and run hotter.

- Watch the aftertreatment: Resolve DPF/catalyst faults quickly to keep backpressure—and turbo temps—under control.

Bottom line: Turbo failure isn’t rare, but it’s avoidable. With regular maintenance, smart driving, and quick action when symptoms appear, a Mercedes turbo can run well past 100,000 miles—keeping your car smooth, efficient, and strong.

Final Thoughts

Turbo issues don’t fix themselves. Catch the signs early, diagnose the root cause, and repair it right the first time. With correct oil, clean intake plumbing, healthy aftertreatment, and sensible warm-up/cool-down, your Mercedes turbo can run strong for years.

Ready for help?

Contact us now to book a diagnostic with our team of experts at A1 Diesel and keep your Mercedes running smoothly.

Frequently Asked Questions

How long do Mercedes turbos last?

With proper maintenance, 100,000+ miles is common. Heat, oil quality, and backpressure make the difference. Check out our guide, How Long Will Your Engine’s Turbocharger Last?, for more information.

Which fault codes point to turbo trouble?

Underboost/overboost, actuator control errors, and airflow plausibility faults. Live data confirms what the codes suggest.

Do I need to replace oil lines with the turbo?

Highly recommended. Coked or restricted lines can ruin a new turbo fast.

Can I replace just the actuator?

Sometimes. If the turbo is mechanically sound and the actuator failed, replacement and calibration may solve it.