Heavy equipment is the backbone of many industries, from construction to mining. But when your diesel engine starts showing signs of trouble, it can quickly bring work to a halt, leading to costly downtime.

Recognizing the early warning signs of engine problems is key to preventing bigger, more expensive repairs down the line.

In this guide, we’ll walk you through the common indicators that your heavy equipment’s diesel engine needs attention and explain why timely repairs are essential to keep your operations running smoothly.

What Is Heavy Equipment Diesel Engine Repair?

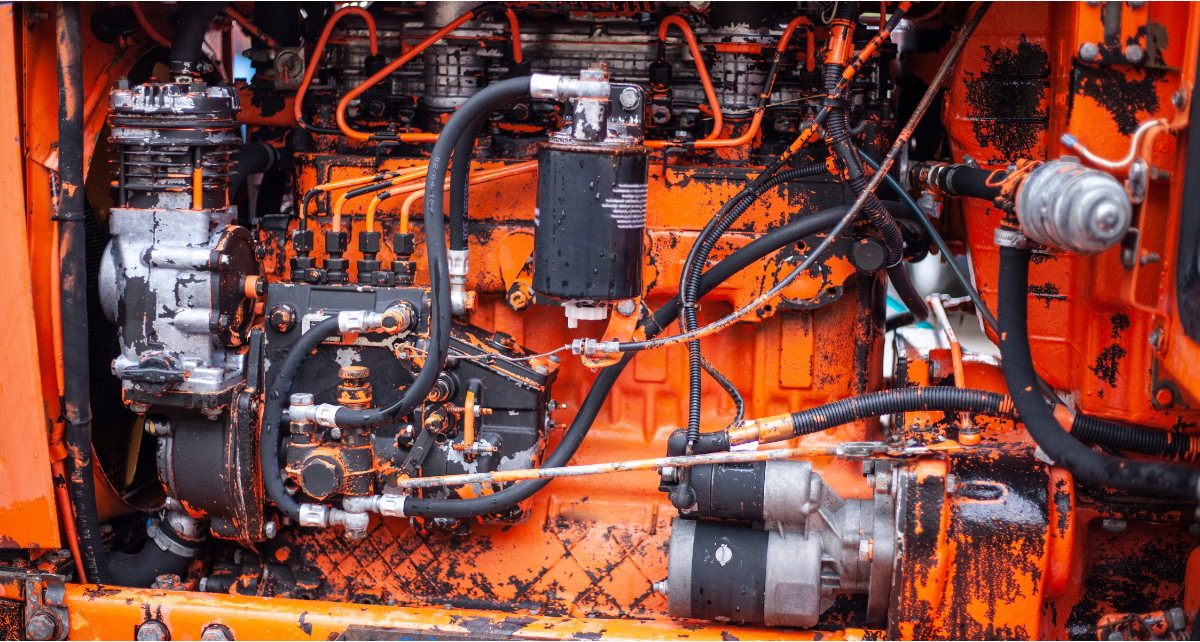

Heavy equipment diesel engine repair involves fixing or restoring any malfunctioning components of a diesel engine in large machines. These engines power essential equipment like bulldozers, excavators, and loaders, as well as diesel trucks and other heavy machinery.

Diesel mechanics, diesel technicians, and other skilled technicians are responsible for maintaining and repairing diesel engines and equipment to ensure reliable operation.

Becoming a diesel mechanic requires completing a diesel technology program or similar training program, gaining hands-on experience, and developing a thorough understanding of diesel technology and industry standards.

Common Issues in Heavy Equipment Diesel Engines

Understanding the typical problems diesel engines face can help identify issues early, reducing repair costs and downtime.

- Poor Fuel Injection: When the fuel injectors malfunction, it can lead to poor fuel combustion, causing the engine to run inefficiently or even stall.

- Dirty Air Filters: A clogged air filter restricts airflow to the engine, reducing its performance and efficiency.

- Cooling System Failures: Overheating is a common issue in diesel engines. This could be due to a faulty radiator, thermostat, or cooling fan.

- Low Compression: This occurs when the cylinders fail to generate enough pressure, affecting the engine’s power and performance.

- Oil Leaks: Leaking oil can cause engine parts to wear prematurely and lead to significant damage if not addressed quickly.

Signs Your Heavy Equipment Diesel Engine Needs Repair

Identifying issues early in your diesel engine helps prevent costly repairs. Routine inspections are essential for ensuring safety and for identifying issues across a range of diesel vehicles and equipment. Here are some signs that your engine may need attention.

Loss of Power

A noticeable drop in power or difficulty handling normal loads indicates the engine is struggling. This can stem from fuel delivery problems, clogged air filters, or more severe internal issues, affecting both performance and fuel efficiency.

Excessive Smoke

Excess smoke from the exhaust is a red flag. White exhaust smoke may point to a coolant leak, blue smoke suggests burning oil, and black exhaust smoke indicates excess fuel burning. Any of these require prompt attention to avoid further damage.

Strange Noises

Unusual sounds like knocking or grinding are often signs of internal engine problems, such as worn bearings or faulty fuel injectors. Addressing these noises early can prevent more serious damage and costly repairs.

Increased Fuel Consumption

A sudden rise in fuel consumption is a sign of inefficiency, possibly due to faulty injectors or blocked filters. This reduces engine performance and increases costs, making it essential to monitor fuel usage.

Warning Lights

Modern diesel engines have diagnostic systems that trigger warning lights for issues like low oil pressure or overheating. Ignoring these lights can lead to serious problems, so it’s important to address any that appear promptly.

The Diesel Engine Repair Process

When your heavy equipment’s diesel engine malfunctions, it’s essential to seek professional repair services. Skilled technicians follow a structured process to diagnose and fix issues, restoring the engine to its optimal condition. Here’s an overview of the key steps involved in diesel engine repair.

Inspection and Diagnosis

The repair begins with a detailed inspection. A technician assesses the engine, checking components like the fuel system, air filters, and oil levels. Using diagnostic tools, they pinpoint the cause of the problem, whether it’s a drop in performance, unusual noises, or excess smoke.

Disassembly and Inspection

Once the issue is diagnosed, the technician may disassemble the engine to inspect internal parts. This allows them to check for signs of wear or damage, such as cracks or corrosion, that could be affecting performance. Hidden problems often emerge during this stage, which could alter the repair plan.

Parts Replacement

Any damaged or worn-out components, such as fuel injectors, filters, or gaskets, will be replaced with high-quality, OEM parts. Using quality replacements ensures durability, enhances engine performance, and helps prevent future breakdowns.

Reassembly and Testing

After replacing the parts, the technician reassembles the engine, ensuring proper alignment. The engine is then tested to ensure it runs smoothly, checking for appropriate fuel consumption and eliminating abnormal sounds or vibrations.

Final Check and Return to Service

Before returning the equipment to service, a final inspection ensures all components are functioning correctly. A test run confirms the engine is operating under load, and the technician provides recommendations for future maintenance to keep the engine running efficiently.

Preventing Future Repairs

While repairs are sometimes unavoidable, there are several steps you can take to prevent future issues and keep your diesel engine running smoothly:

- Establish a Preventative Maintenance Schedule: Work with a professional to perform routine inspections and set up regular diesel engine maintenance for your equipment.

- Train Operators: Ensure that equipment operators are properly trained in operating machinery efficiently to reduce the risk of engine strain.

- Monitor Performance: Keep track of any changes in the equipment’s performance, such as increased fuel consumption or unusual noises.

Final Thoughts

Proper diesel engine repair is crucial to keeping your heavy equipment running efficiently and avoiding costly downtime. By addressing issues early and following a thorough repair process, you can extend the life of your equipment and maintain peak performance.

At A1 Diesel, we specialize in expert diesel engine repairs, ensuring your machinery stays in top shape and gets back to work as quickly as possible.

If you’re experiencing engine issues, don’t wait until it’s too late. Contact A1 Diesel today for professional, reliable service and expert repair solutions. Let us keep your equipment running smoothly—because when your engine runs well, your business does too.

Contact us now at A1 Diesel for a consultation or to schedule your repair.

Frequently Asked Questions

Why should I choose A1 Diesel for my diesel engine repairs?

At A1 Diesel, we specialize in diesel engine repair, providing expert diagnostics and high-quality repairs. With years of experience and a commitment to excellent customer service, we ensure that your equipment is back up and running quickly and efficiently. Trust us to handle all your diesel engine needs!

Can I continue using my equipment if the warning light comes on?

It’s never advisable to ignore a warning light. While some lights might indicate minor issues, others can signal serious problems like low oil pressure or overheating. Continuing to operate the equipment without addressing these issues can lead to further damage and costly repairs.

How can I prevent diesel engine failures?

The best way to prevent diesel engine failure is through regular maintenance. This includes monitoring oil levels, checking fuel injectors, changing filters, and conducting periodic performance checks. Training operators to use equipment properly is also crucial to avoid putting undue strain on the engine.

Can I repair the diesel engine myself?

While it’s possible to perform minor maintenance tasks, such as changing air filters or replacing fluids, repairing a diesel engine requires specialized knowledge of heavy equipment repair and tools. For more complex issues, it’s always recommended to consult a professional diesel mechanic to avoid causing further damage to the engine.