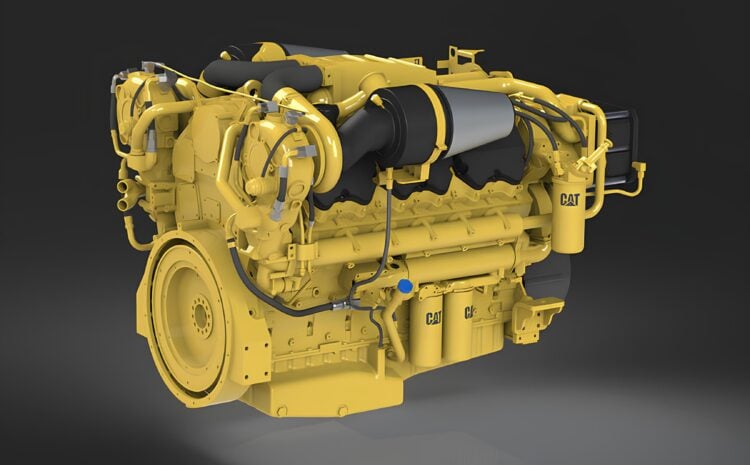

The Caterpillar V12 engine is one of the toughest and most reliable engines used in heavy-duty equipment such as mining trucks, construction machinery, and industrial generators. Known for its torque, durability, and ability to perform in harsh environments, it has become a trusted choice for operators worldwide.

However, even a workhorse like the CAT V12 is not immune to problems. One of the most common and costly issues owners face is CAT V12 pump failure. When the fuel pump stops working correctly, the entire machine can grind to a halt, leading to downtime, expensive repairs, and lost productivity.

This guide explains what causes CAT V12 pump failure, the warning signs you should look out for, and the best steps to prevent pump damage.

What Causes CAT V12 Pump Failure?

A fuel pump failure in a CAT V12 engine can stem from multiple factors. The most common include:

Fuel Contamination

Dirt, water, and other particles in the fuel system can wreak havoc on the high-precision internals of the fuel pump. Even a small amount of debris can damage seals, wear down components, and eventually lead to full pump failure. Check out our guide on what happens when water mixes with fuel to learn more.

Poor Fuel Quality

Using low-grade diesel or fuel that doesn’t meet CAT’s specifications can cause increased stress on the pump. This can lead to inefficient combustion, poor engine performance, and, over time, pump damage.

Overheating and Lubrication Failure

The fuel pump doesn’t just move fuel; it also relies on fuel as a lubricant. If there’s air in the system or the engine is running too hot, the pump can be deprived of adequate lubrication, causing it to seize or wear out prematurely.

Age and Wear

These engines are built tough, but nothing lasts forever. If your CAT V12 has racked up a high number of operating hours, natural wear and tear could simply be catching up with the pump.

Other Contributing Issues

Issues with the cooling system, coolant leaks, and oil contamination can also contribute to or be mistaken for pump failure.

It’s important to check the water pump, oil pan, oil seal, hoses, gear train, and the weep hole area for any signs of leaks or wear. Coolant leaking into the oil, or oil leaks from worn seals, can lead to engine overheating and further damage.

Inspecting and replacing faulty components, such as the water pump, hoses, or oil seals, can help prevent further issues and ensure the engine operates efficiently.

Signs of Fuel Pump Trouble

Catching pump issues early can save you thousands in repair costs and minimize downtime. Here are some common warning signs that your CAT V12 pump may be failing:

- Hard starting or no start: If the engine struggles to turn over or refuses to start at all, the fuel pump could be struggling to deliver adequate pressure.

- Loss of power: A drop in engine performance or inconsistent power delivery is often a sign the pump isn’t doing its job properly.

- Black smoke or white smoke from the exhaust: These can be signs of incorrect fuel injection timing or incomplete combustion due to fuel delivery problems. Check out our guides on black smoke in the exhaust system and white smoke from the exhaust for more information.

- Unusual noises: Grinding, whining, or knocking sounds from the fuel pump area are never a good sign.

- Error codes or warning lights (if your equipment has diagnostics): Modern machines may flag a fault code for low fuel pressure or pump malfunction.

If you notice any of these symptoms, it’s important to find the right fix as soon as possible to prevent more serious engine damage.

What to Do If Your CAT V12 Pump Fails

If you suspect your fuel pump has failed, it’s best not to guess. Have the machine diagnosed by a professional technician with CAT-specific tools and software. In many cases, the pump will need to be rebuilt or replaced, and it’s crucial that the rest of the fuel system is checked to avoid repeating the issue.

The CAT V12 is an engineering masterpiece, but like any high-performance machine, it depends on a healthy fuel system to deliver power. Fuel pump failure is a serious issue, but with proper maintenance, quality fuel, and early detection, you can keep your CAT running strong for years to come.

Whether you’re operating a quarry, managing a construction fleet, or running a remote power station — staying ahead of pump problems means less downtime, more productivity, and better peace of mind.

How to Prevent CAT V12 Pump Failure

Fortunately, many pump failures are preventable with routine diesel engine maintenance and smart operating practices.

- Use clean, high-quality fuel and store it in contamination-free tanks.

- Change fuel filters regularly, and inspect them for signs of rust, debris, or water.

- Monitor engine temperature and don’t overwork the engine beyond its design limits.

- Bleed the fuel system properly after filter changes or when refueling from empty to avoid air pockets.

- Schedule regular inspections by qualified technicians, especially if your equipment runs in tough conditions.

Keep Your CAT V12 Running Strong

The CAT V12 is built to deliver power and reliability in the toughest conditions, but fuel pump failure can bring even the hardest-working machine to a standstill. By understanding the causes, spotting early warning signs, and following a solid maintenance routine, you can avoid costly downtime and keep your equipment performing at its best.

If you’re dealing with CAT V12 pump failure or want expert support to prevent it, A1 Diesel is here to help. Our team specialises in diesel engines, including fuel system repairs, providing the diagnostics, rebuilds, and replacements you need to get back to work quickly.

Contact A1 Diesel today to schedule service or speak with a technician about your CAT V12 pump issues.

Frequently Asked Questions

Can CAT V12 pump failure damage other engine components?

A failing pump can cause poor combustion, overheating, and increased stress on injectors and other fuel system parts. If left unresolved, it may even lead to piston or cylinder damage. That’s why catching pump issues early is so important.

Is it better to rebuild or replace a CAT V12 fuel pump?

If the pump is only moderately worn, a rebuild by a qualified technician can restore performance and extend its lifespan. In cases of severe wear, cracks, or internal damage, replacement is usually the more reliable long-term solution.

What tools are used to diagnose CAT V12 pump failure?

Professional technicians often use Caterpillar-specific diagnostic software, fuel pressure gauges, and electronic control module (ECM) readings. These tools help pinpoint whether the pump is failing or if another component in the fuel system is causing the problem.